1. Model and selection guide of special reducer for mobile robots (AGV, AMR)

2. The difference between AGV laser SLAM navigation and visual SLAM navigation

3. Check it out! An article to understand these navigation and guidance methods of AGV robots

With the gradual development of factory automation and computer integrated manufacturing system technology, as well as the wide application of flexible manufacturing systems and automated three-dimensional warehouses, AGV (Automated Guided Vehicle) is used to connect and adjust discrete logistics management systems to make operations continuous. It is necessary to automate the handling and loading and unloading methods, and its application scope and technical level have been developed rapidly. As an innovator in the field of system-level motion control, kinco continues to use advanced motion control technology and technology to help customers efficiently, accurately and flexibly complete material handling. Transportation tasks to meet the application needs of customers for more flexible logistics handling systems, automated three-dimensional warehouses, etc. WeChat public account: Industrial Control Sharing

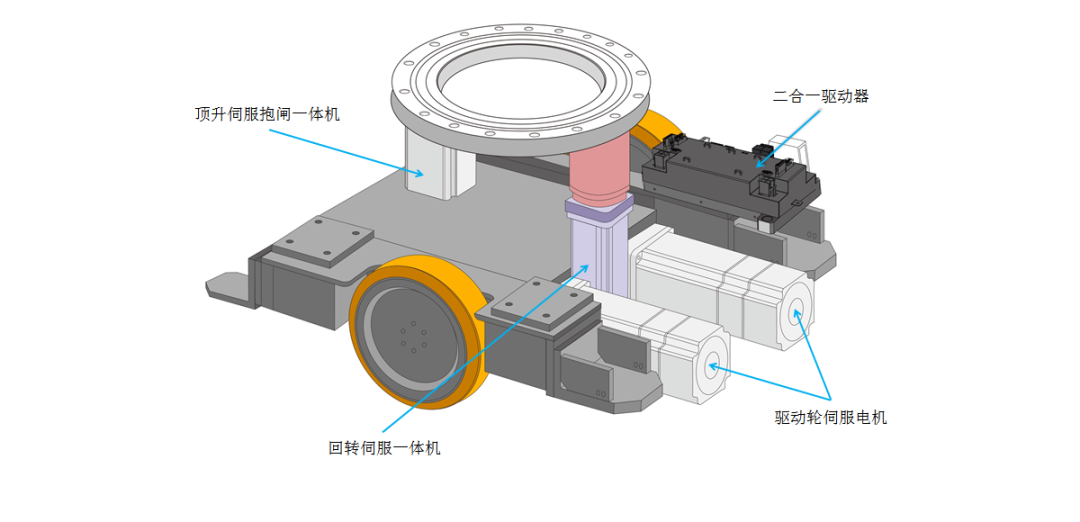

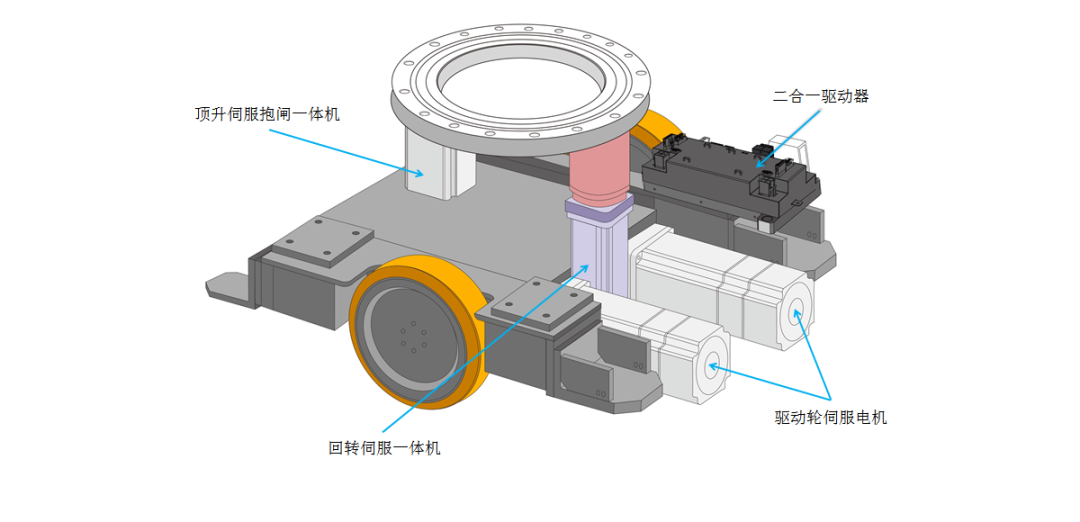

The basic structure of AGV

The basic structure of AGV stand-alone hardware includes car body, power storage and charging device, drive device (car body operation, steering, brake adjustment), guiding device, information transmission and processing device, safety protection device, transfer device (jacking, mechanical arm grab, roller, belt)

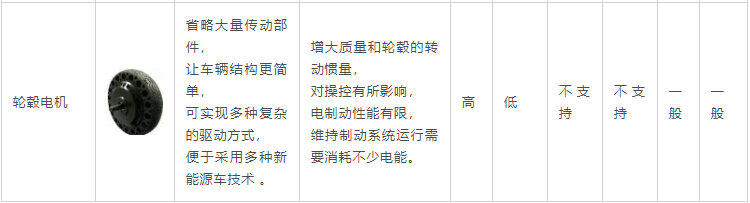

The motors used in the AGV stand-alone machine can be mainly divided into the motors above the table and the jacking motors below the table, slewing motors and drive wheel motors (mainly including wheel motors, hub motors, Mecanum types, etc., among which wheel motors are used. There are three types of single steering wheel type, double steering wheel type and differential wheel type), the advantages and disadvantages and characteristics of the drive wheel motor are compared as follows: WeChat public account: Industrial Control

■ FD1X4S series low voltage servo driver main features

? Support single axis, two in one;

? Support pulse;

? Support Modbus\Canopen\EtherCAT communication control;

? Low-voltage DC power supply to meet the power and power supply requirements of mobile trolleys;

? New miniature terminal design, more compact and more beautiful appearance;

? The maximum 3 times overload design improves the response speed of the car when starting and stopping;

? Overcurrent, overheating, overvoltage, motor IIt protection to ensure the safety of the drive system;

? The whole series of products have passed CE certification and comply with ROHS environmental certification standards;

■ MD Series Integrated Low Voltage Servo Motor Main Features

? Wide power supply range: support 24~70VDC wide voltage;

? Multiple power options: 200~750W multiple power options;

? Small product size: the driver and the motor are integrated and the structure space is more compact;

? Strong overload capacity: 3 times overload capacity;

? Wide range of communication methods: support RS232, CANopen, Modbus RTU, EtherCAT, etc.;

? High safety performance: with overvoltage protection, undervoltage protection, short circuit protection, motor overheating (I2T) protection, driver overheating protection and other safety protection measures;

? Full dedicated functions: Added functions such as alarm synchronous braking, enhanced battery life and other logistics industry-specific functions.

WeChat public account: Industrial Control Sharing

■ OD1X4S series low voltage servo driver main features

? Compared with the low-voltage drivers of mainstream manufacturers in the market, with the careful circuit design, the whole machine is only the size of a palm;

? High performance, high efficiency and safety, the driver can be installed in any position of the equipment, so that the customer's equipment has lower energy consumption, stronger performance and smaller size;

? Match 50W-750W low voltage magnetoelectric encoder & incremental encoder motor;

? Support CANopen, Modbus, EtherCAT bus communication;

? Reserve various I/O interfaces to meet the customer's system control requirements to the greatest extent;

? Modular design, rich product series, can meet the customized needs of customers;

? Easy to embed in customer control panel.

WeChat public account: Industrial Control Sharing

New Generation G2 Series Servo Motor

New electromagnetic design Small cogging torque, low torque ripple, and vibration during motor operation, making torque output more stable

Short fuselage design The fuselage structure is redesigned to shorten the length of the fuselage, save more installation space and reduce the size of the equipment

The latest magnetic coding technology Self-designed magnetoelectric encoder with good shock resistance and high cost performance

Insulation class F-class The motor is at the highest insulation class level in the industry, and has high reliability and stability under high temperature extreme environments.

WeChat public account: Industrial Control Sharing

■ In-wheel motor it is a motor designed by integrating the power system, transmission system and braking system, omitting a large number of transmission components, making the vehicle structure simpler, and realizing a variety of complex driving methods. Therefore, whether it is front-wheel drive, rear-wheel drive or four-wheel drive, it can be implemented relatively easily, even full-time four-wheel drive is easier to implement on in-wheel motor-driven vehicles.

Features:

??Compact structure and easy installation

??High rated torque and strong bearing capacity

??Meet customers' requirements for quietness

??Can be equipped with different precision encoders to meet customer's precision requirements

??Can be flexibly customized according to customer needs

Due to the variety of AGV products on the market and various functional requirements, if you have any needs, please consult the technical staff of kinco.

This news information comes from - Industrial Control Sharing.